-

Main applications

#1 - Transfer of cases and cartons on one or more lines

- Feeding and distribution of empty cases on manual stations, automated packing stations.

- Feeding and distribution of full cases to automatic palletizing equipment

- Possibility of crossing doors, partitions, connection to downstream conveyor systems

# 2 - Overhead conveying of empty or full cases

- Feeding of the various packaging stations on the ground with different descending conveyor lines if necessary

- Saving space on the ground thanks to the installation of a self-supporting structure on the ground or suspended from the frame, depending on the layout of the production unit

#3 - Collection and sorting of packages from several lines

- Sorting according to the reference of the package scanned at the exit of the case packer

- Routing of cases to the correct conveyor lines

#4 - Case stacker

- Compact equipment

- Choice of the number of boxes in the stack

- Constant entry and exit height

- Fully autonomous module with its own case

- Secure equipment, no enclosure required

#5 - Elevation of cases (elevator, lifter, spiral, etc.)

- Reduced footprint and space saving on the ground

- Ability to support different case formats

- Choice of technology according to the rates

- Different configurations possible depending on the installations (adaptation of dimensions and heights according to customer constraints)

-

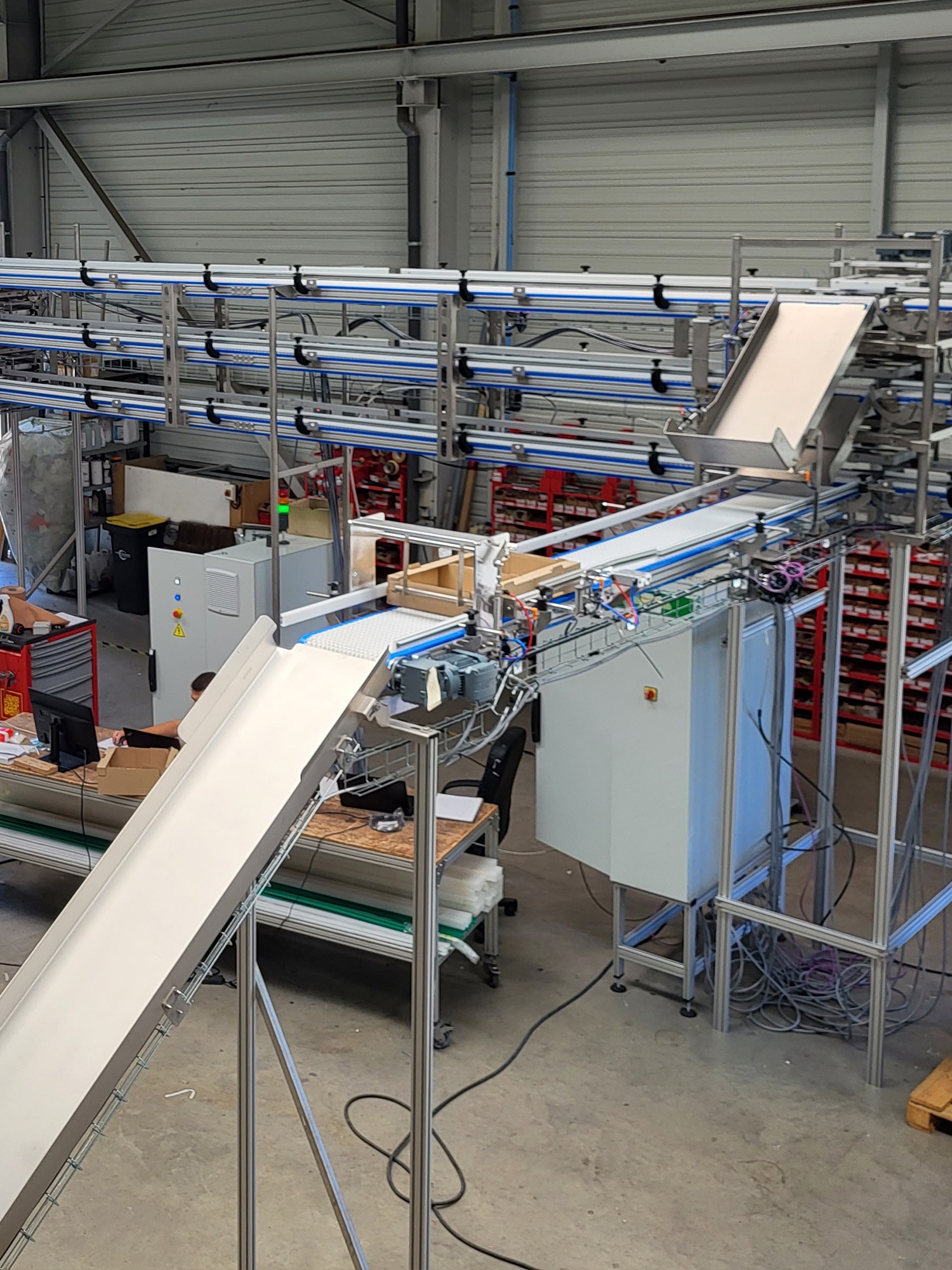

Examples of case conveying solutions

Project #1 - Complete circuit of full case conveyors

PROJECT DESCRIPTION

Our client, producing snack products for mass-market retailers, wanted to modernize its production facilities by investing in new machines. MG Tech supplied a complete line including case erectors, top-load case packers, a product mixing machine, and all the conveyor lines. These included a complete system of conveyors for full cases from the case packers to the palletizers and/or the mixing machine.

PROJECT FEATURES

- Conveyor length: 11 m

- Height: Overhead conveyor at a height of 6,400 mm from the ground (at its highest point), ground conveyor at a height of 900 mm

- Conveyor types used: aluminum and stainless steel conveyors, modular and PVC belts, roller conveyors

- Additional integrated equipment: a double elevator, motorized pusher to send the crates to the second conveyor line

Project #2 – Transfer of empty cases to collector and case packing stations

PROJECT DESCRIPTION

A ready-meal manufacturer wanted to implement an overhead transfer system for empty cases from case formers to collectors to supply the automated case-packing stations of the five ready-meal production lines. MG Tech also supplied the end-of-line packaging equipment, facilitating setup and communication between the machines and the conveyor belts.

PROJECT FEATURES

- Total conveyor length: 30 meters

- Conveyor width: 300 mm

- Average case rate: 10 cases/min

- Conveyor types used: modular aluminum conveyor

Project #3 – Manual picking and order preparation station

PROJECT DESCRIPTION

For a meat industry manufacturer, MG Tech supplied a manual picking and order preparation system. The line consists of 36 conveyor lanes divided into two levels for sorting cases by reference. A barcode scanning control system allows cases to be differentiated and distributed onto the correct lanes. A transverse conveyor line allows an operator to retrieve cases from a series and send them to a manual palletizing platform equipped with a lifting table for more ergonomic operator movements.

PROJECT FEATURES

- Conveyor length: 300 meters

- Number of lanes: 36 lanes spread over 2 levels

- Case rateExam: 16 cases/minute

- Conveyor types used: roller conveyors and modular belt conveyors

-

Do you need further information? Contact us now