Key figures

Number of arrivals

Palletization height

Maximum pallet dimensions

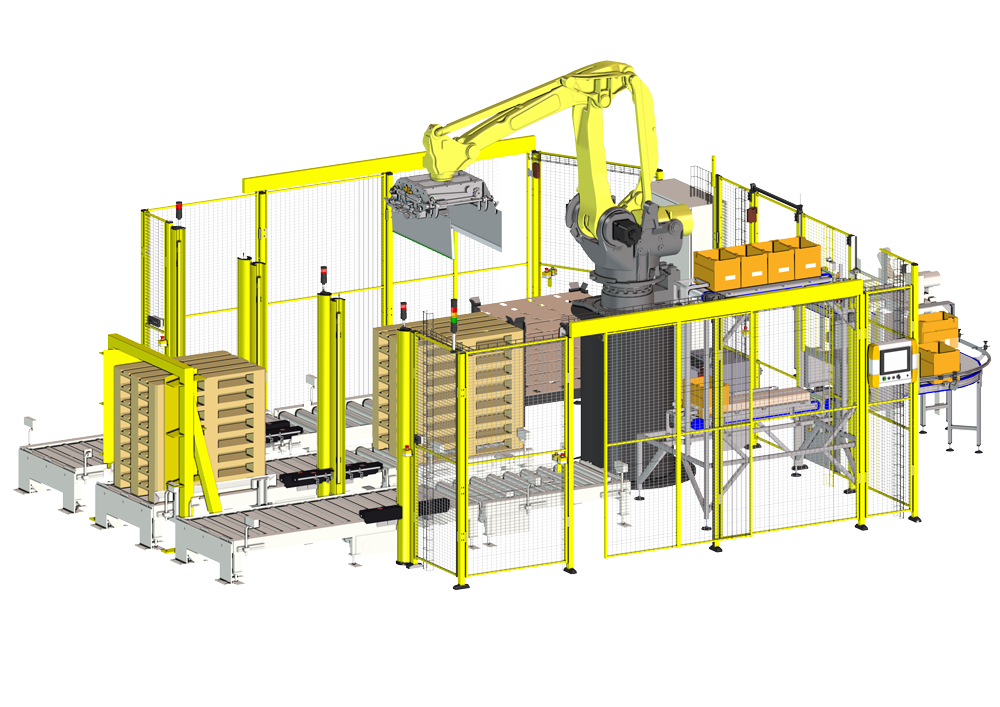

Machine features

- Type of palletization: columnar, crossed layers, with or without clearance, with cooling stack, with pallet overhang, etc.

- Type of gripper: by vacuum, by grippers or by shovel

- Package gripping: by unit, by row, by layer

- Pallet management: manual or automatic with conveyors

-

Technical features & benefits

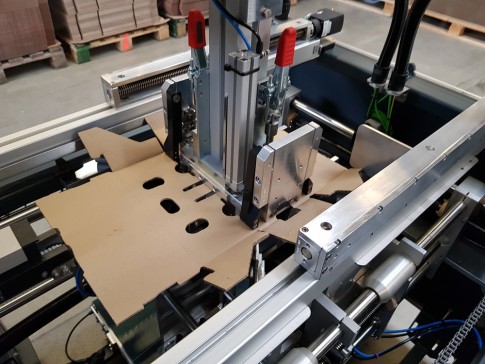

#1 - Flexible and adaptable equipment

The MG Tech robotic palletizer is a system capable of adapting to a wide variety of configurations, carton sizes, and palletizing schemes. This allows companies to use it for different production lines without the need for major modifications, which is particularly advantageous for those that handle varied products. Our robotic palletizers integrate robots from our preferred partners, such as Fanuc or Yaskawa, with whom we are used to collaborating. All our palletizers can integrate additional functions such as a slip station (in flat or corrugated cardboard), a parcel grouping station or external equipment (labeler, weight control, pallet wrapping, etc.).

#2 - Precision and reliability

The MG Tech robotic palletizer stands out for its precision and reliability. Thanks to cutting-edge technologies, it ensures perfectly stable and uniform stacking, thus reducing the risk of spillage or damage to products during transport. This precision is essential to guarantee the quality of the pallets and minimize losses due to handling errors.

#3 - Increased productivity

Speed is another key advantage of the MG Tech robotic palletizer. Capable of operating at high speeds, it allows the palletizing process to be accelerated, thus contributing to an overall increase in productivity. This speed does not affect the quality of the work, as the robot maintains high performance even during intense production cycles.

#4 - Energy efficiency

Finally, the energy efficiency of the MG Tech robotic palletizer is an important advantage for companies concerned with reducing their carbon footprint and energy costs. Designed to consume less energy while maintaining optimal performance, this system is part of a sustainable development approach while optimizing operational expenses.

-

Do you need further information or a quotation?

-

Additional functions of robotic palletizer for a complete line