Key figures

Number of case

Speed/robot

Footprint

Machine features

- Storage type: flat or upright

- Case types: 4 corners glued cases, shelf-ready trays, trays with ledge, stackable cases

- Product types: pots, pack, case, tri-fold boxes, bottle, thermoformed/sealed/filmed trays, sachet, flowpack/doypack, blisters…

-

Technical features & benefits

#1 - Pick & Place operations agility

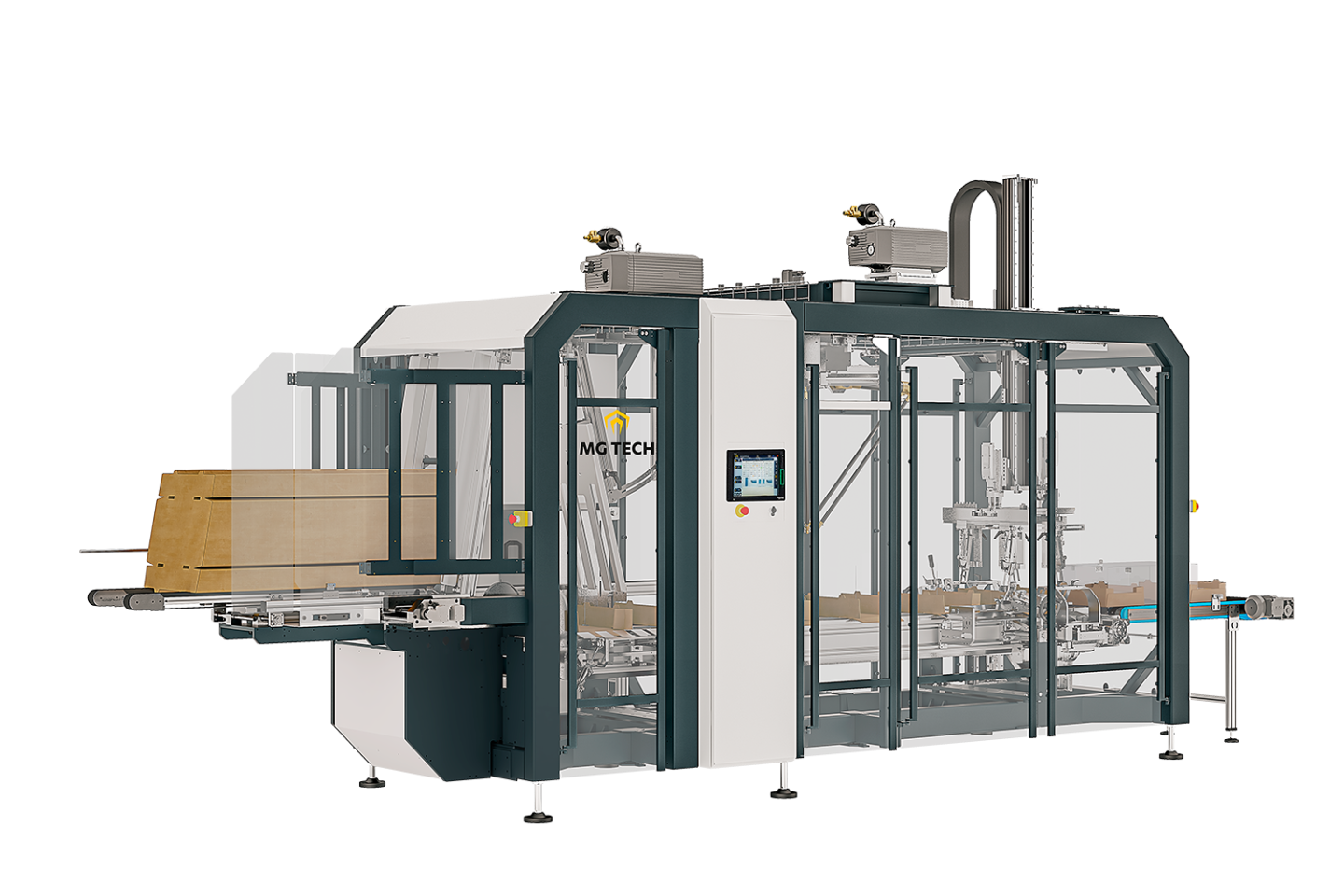

Designed to perform “Pick and Place” operations, each robot is equipped with interchangeable tools capable of performing numerous movements: translation, rotation, tilt, etc. This agility allows the different MG Tech robots to adapt to all types of products and to easily store products in the boxes. The MG Tech's wish to use robotic solutions as a priority for loading products into boxes make case packers very evolutive to the products and cases of tomorrow.

In addition, in its developments, MG Tech has a global vision of end-of-line mechanization needs (batching, loading or unloading of products, on-packaging, etc.). The products and in particular the MG Tech robots are thus completely adapted to all applications of your production lines.

#2- Ergonomic & safe equipment

The cardboard magazine has a large autonomy and capacity. It has been designed to be located at 900 mm from the floor. Guard doors and blank presence sensors have been added to secure the cardboard magazine.

The wrap-around case packer is equipped with full height front and rear access doors for easier maintenance operations. The case circuit is totally accessible, the case closing stations mounted on Brushless axes can be released for troubleshooting.

#3- Increased productivity

Our wrap-around case packer is connected through OPCUA. All use and operation parameters are available on the 12’’ HMI screen allowing to optimize the production when necessary.

For better productivity, additional accessories can be added inside the machine and connected to the HMI, such as colored LEDs to visualize and analyze the operations in progress or the defaults or IP cameras to record operations and understand recurring issues.

#4 - Modularity and evolutivity

All our wrap-around case packers can be adapted for different case formats. The format changeovers are easy and quick to operate as they require any tools. They can be all automated or controlled & assisted with guidance on the HMI screen.

The range of wrap-around case packers includes several sizes of machines depending on production rates, products to pack and cardboard cases.

-

Réalisations commerciales

Cliquez sur la vidéo pour en savoir plusEncaisseuse wrap - Sachets de viande

Découvrez notre réalisation commerciale pour l'encaissage wrap de sachets de viande pour le secteur boucherie/charcuterie.

Regardez la vidéo pour en savoir plus.Encaisseuse wrap - Flacons en plastique

Découvrez notre réalisation commerciale pour l'encaissage wrap de flacons en plastique pour le marché de la pharma-cosmétique.

-

Do you need further information or a quotation?

-

Additional packing functions to complete packaging line