-

Main applications

#1 – Pallet transfer

- Different types of conveyors: roller, chain, modular

- Integration of a rotating table to facilitate pallet wrapping

- Integration of a pallet centering device

- Integration of additional equipment (strapping, wrapping, identification and labeling, etc.)

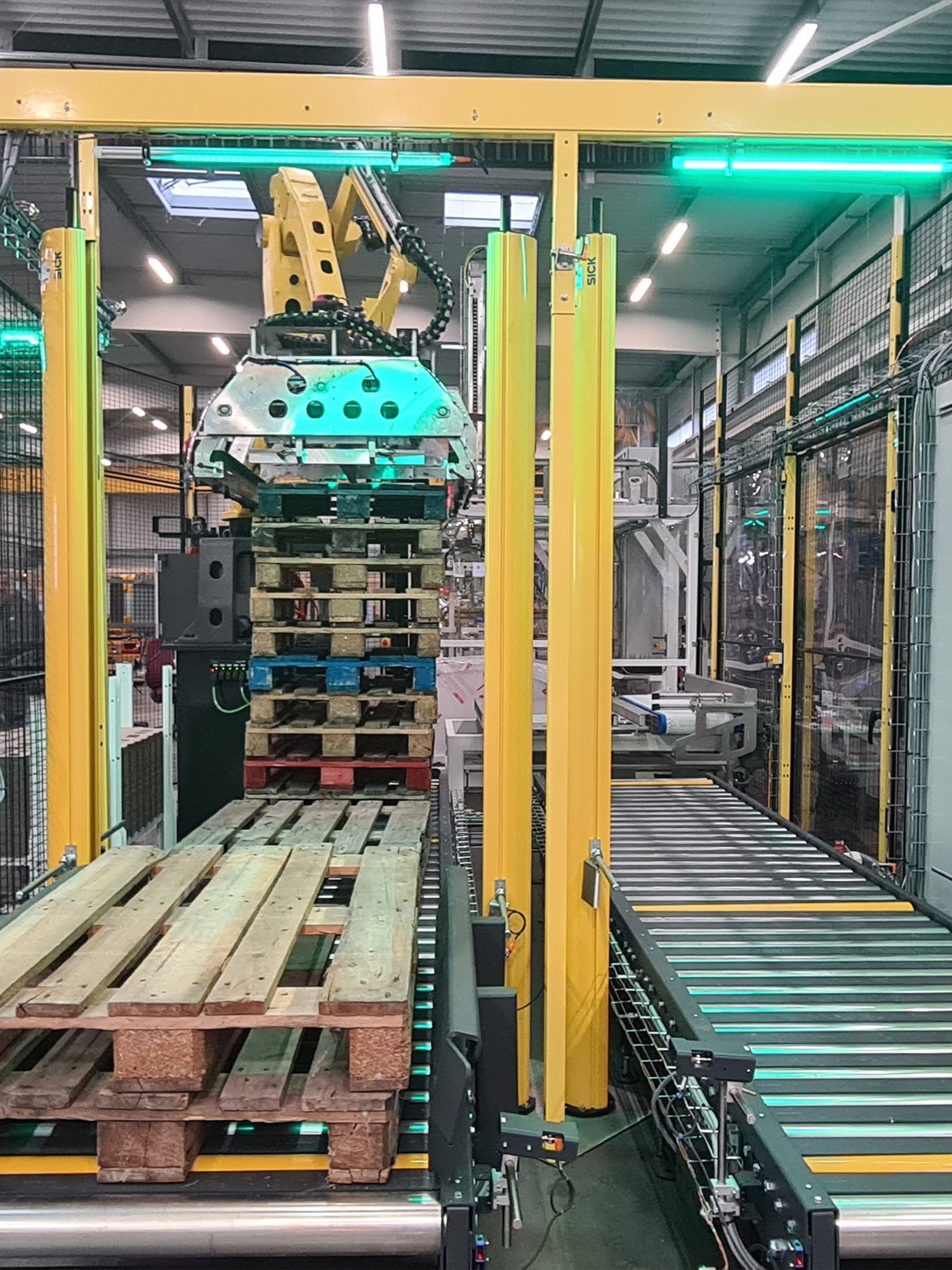

# 2 – Pallet transfer in palletization equipment

- Empty pallet feeding conveyor lines

- Palletizer outlet conveyor lines for finished pallets

-

EXAMPLES OF PALLET CONVEYING SOLUTIONS

Project #1 – Low level pallet conveyors

PROJECT DESCRIPTION

For a bakery manufacturer, MG Tech supplied a set of low-level conveyors for packaging its pallets. The low-level conveyors are positioned upstream of the packaging equipment for the entry of empty pallet stacks and at the exit for the removal of finished pallets. The system is perfectly safe and ergonomic for operators; there are no protruding casings, and the decking is integrated.

PROJECT FEATURES

- Pick-up/drop-off height: 90 mm

- Production rate: 19.5 pallets/hour

- Conveyor types used: low-level roller conveyors

Project #2 – Stock of pallet stacks and strapping line

PROJECT DESCRIPTION

As part of the implementation of a new production and packaging line in its factory, our client also had to invest in new equipment for the packaging and logistics of its full cardboard pallets. MG Tech therefore designed and supplied conveyor systems for the transfer of full pallets to the strapping and labeling areas (integration of ancillary equipment) as well as a conveyor line to manage the dynamic storage of stacks of empty pallets awaiting collection by an MG Tech mobile robot.

PROJECT FEATURES

- Conveyor height: 500 mm

- Finished product pallet rate: up to 51 pallets/hour

- Empty pallet stack rate: up to 6 pallets/hour

- Conveyor types used: roller conveyors

-

Do you need further information about our pallet conveying solutions? Contact us